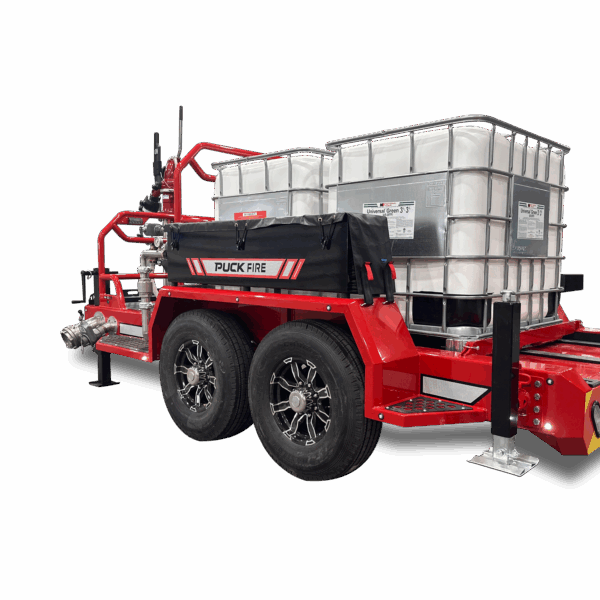

Foam Tote Trailer

Puck’s Foam Attack Tote Trailer is a quick deploying, mobile discharging platform compatible with both 275 gallon and 330 gallon foam concentrate totes. Increase versatility of your foam tote concentrate delivery operations with a manifold that provides equal distribution, simultaneously, to three lines with self-educting monitors and nozzles. Eductors on the driver and passenger sides connect to attack hose kept in the storage boxes above the wheels. A standard TFT monitor and nozzle on the riser pipe at the front of the trailer can be used for manual foam application. Alternatively, it can perform vessel cooling with clean water while the front pipe is connected to hose to apply foam further away from the trailer. The foam manifold under the working platform ensures that three of the four possible foam lines have equal access to foam concentrate while running simultaneously.

Dual 5” Storz inlet connections sit at each side of the front of the A-frame trailer for efficient water supply with a flow rate up to 2,000 GPM. Foam flush lines can clear the lines of excess foam, as well as act as a bypass to foam totes when connected to a tanker. Manual jacks on each corner ensures the trailer sits level when placed on uneven ground. The Foam Attack Trailer’s chassis is powder coated for durability and easy cleaning after use and provides 11-½” of ground clearance.

Foam concentrate totes can be locked into place for road travel, so your team is always ready for fast deployment. The sides of the trailer above the wheels feature storage for fire hose. The trailer is built with quick foam tote change out features to minimize downtime of foam concentrate delivery. The Puck Foam Tote Trailer also features a range of one to three tote carry capacity configurations, with optional dry chemical skid capabilities to custom build a mobile firefighting unit that fits your industrial fire or municipal fire needs.

A New Approach to Bringing Water to the Fire

Tote Trailer Features

- Flow rates from 500 to 2,000 GPM

- 4 corner jacks for stability

- Pre-piped single waterway aluminum monitor with flow rates up to 2,000 GPM

- Storage capacity for up to 990 gallons of foam concentrate

- 5” Storz inlet connections on each side

- 2-1/2″ U.S. Coupling gate valves

- Built-in toolbox

- System ability to be completely backflushed

- Optional hose bin eductors

- Optional dry chemical skid unit

Lighting

- LED lights on the work platform for a safe working area

- Undercarriage lighting

- Red and white emergency flashing lights

Applications

- Foam Suppression on Chemical Fires

- Airport Storage

- Foam Concentrate Mixing

- Fire Protection for your Property