LightSpeedTM

$500,00 – $2.000,00

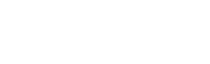

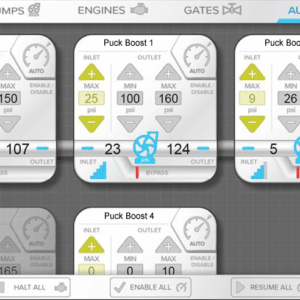

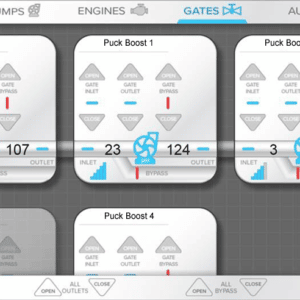

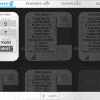

We don’t just build the best pumps — we create the hardware and software that helps them keep that status. LightSpeed is the only control system on the market that offers full site-mapping, in-depth pump diagnostics and insight, allowing you to have remote monitoring and control of your pumps in real time. Control every pump in the line remotely from one connected, web-enabled screen with the LightSpeed control system. With an additional level of safety and security, you can regulate pressures, control gates, and set flows from a distance.

LightSpeed’s built-in pump diagnostics can monitor apparatus engines, relay the status and positions of gates, and more. The telematics system monitors every pump in your operation to detect small issues before they become serious problems. Auto-throttle will adjust pressures automatically based on user-defined inlet and outlet variables to your pump from cavitation and maximize flow rates. With less downtime and fewer catastrophic repairs, your operation can improve efficiency. Standard equipped on all Puck pumps, LightSpeed’s advanced pump protection technology is always keeping an eye on the operation.

Discover how LightSpeed can add value to your manure operation with a video from sales team member Joe Heese. Joe explains the controls, management system, and safety LightSpeed provides for your operation.

LightSpeed Features

- Real-time asset control

- Intuitive, web-based operating platform

- Auto-throttle settings for each unit

- Warning indicator for machine vitals and operating parameters

- Accessible from any connected, web-enabled device